The Key Differences at a Glance

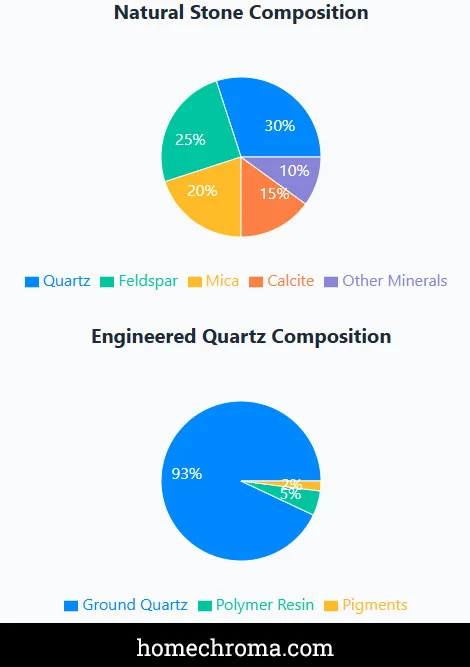

Natural stone comes directly from the earth, formed over millions of years through heat and pressure. In contrast, engineered quartz is manufactured using 90-95% ground natural quartz crystals combined with 5-10% resins, polymers, and pigments.

While granite once dominated the countertop market, engineered quartz has gained significant popularity as homeowners seek lower-maintenance alternatives with consistent designs.

Understanding Natural Stone

What It Is

Natural stone forms deep within the earth’s crust over millions of years when heat and pressure condense various minerals into solid rock. These deposits are eventually pushed upward, creating the quarries from which we extract stone today.

Common Types

- Granite: Strong, durable, and resistant to wear

- Marble: Luxurious appearance with intricate veining patterns

- Quartzite: Hard metamorphic rock similar to marble but more durable

- Limestone: Warm tones, often used for pathways and flooring

- Slate: Fine-grained rock with natural slip resistance

Aesthetic Appeal

Hand-Made Carved Marble Bathroom Sink Natural Stone [click to view…]

Each piece of natural stone offers unique:

- Colors ranging from white and gray to blue, green, and red

- Patterns from subtle veining to dramatic swirls

- Finishes including polished, honed, leathered, and flamed

Understanding Engineered Quartz

Pink Rose Quartz Kitchen Slab [click to view…]

What It Is

Engineered quartz combines ground natural quartz crystals with resins and pigments. The mixture is pressed under high pressure, sometimes with heat, to create dense, non-porous slabs.

Aesthetic Options

Engineered quartz offers:

- Nearly limitless color options (whites, grays, blues, greens, etc.)

- Patterns mimicking natural stone or completely unique designs

- Various finishes similar to natural stone (polished, honed, textured)

- Consistent appearance across slabs

Head-to-Head Comparison

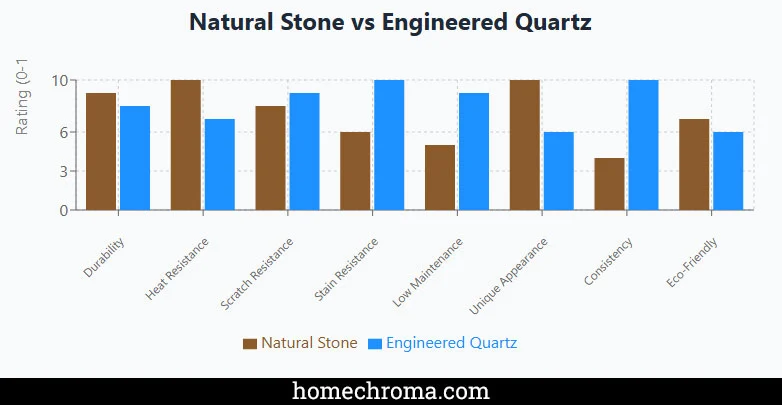

Durability

Scratch Resistance

- Natural Stone: Quartzite (7-8 on Mohs scale) and granite (6-7) are highly scratch-resistant; marble (3-5) scratches more easily

- Engineered Quartz: Excellent scratch resistance (7 on Mohs scale), often harder than granite

Heat Resistance

- Natural Stone: Granite and quartzite handle heat extremely well; marble can tolerate moderate heat

- Engineered Quartz: Resistant to moderate heat but can be damaged above 300-400°F

Stain Resistance

- Natural Stone: Most types are porous and require sealing; granite and marble need regular maintenance

- Engineered Quartz: Non-porous and highly stain-resistant without sealing

Maintenance

Cleaning Requirements

- Natural Stone: Requires specific cleaners for some types; immediate spill cleanup needed

- Engineered Quartz: Simple cleaning with mild soap and water

Sealing Needs

- Natural Stone: Most types need periodic sealing (granite, marble, limestone, slate)

- Engineered Quartz: No sealing required

Cost Considerations

Material Cost (Installed)

- Natural Stone:

- Granite: $30-$150+ per square foot

- Marble: $40-$200+ per square foot

- Quartzite: $80-$220+ per square foot

- Engineered Quartz: $50-$200+ per square foot

Long-Term Expense

- Natural Stone: Higher maintenance costs (sealing, potential repairs)

- Engineered Quartz: Lower ongoing maintenance costs

Environmental Impact

White Quartz Kitchen & Bar Counter Top [click to view…]

Natural Stone

- Quarrying is energy-intensive and disruptive

- Transportation contributes to carbon emissions

- Durable, long-lasting, and recyclable

- Zero VOCs

- Responsible sourcing increasingly emphasized

Engineered Quartz

- Manufacturing is energy-intensive

- Contains non-renewable resins

- Often incorporates recycled materials

- Creates silica dust hazards for fabricators

- Typically has higher carbon footprint

Expected Lifespan

- Natural Stone: Granite/quartzite can last a lifetime; marble 50+ years with proper care

- Engineered Quartz: Typically 15-20+ years with proper care

Applications Beyond Countertops

Flooring

Both materials work well for flooring with different advantages:

- Natural stone offers unique character and, with proper sealing, can last generations

- Engineered quartz provides consistency and requires no sealing, making it ideal for moisture-prone areas

Wall Coverings

- Natural stone adds luxury and texture but installation can be complex

- Engineered quartz works especially well in bathrooms and showers due to its non-porous nature

Making Your Decision

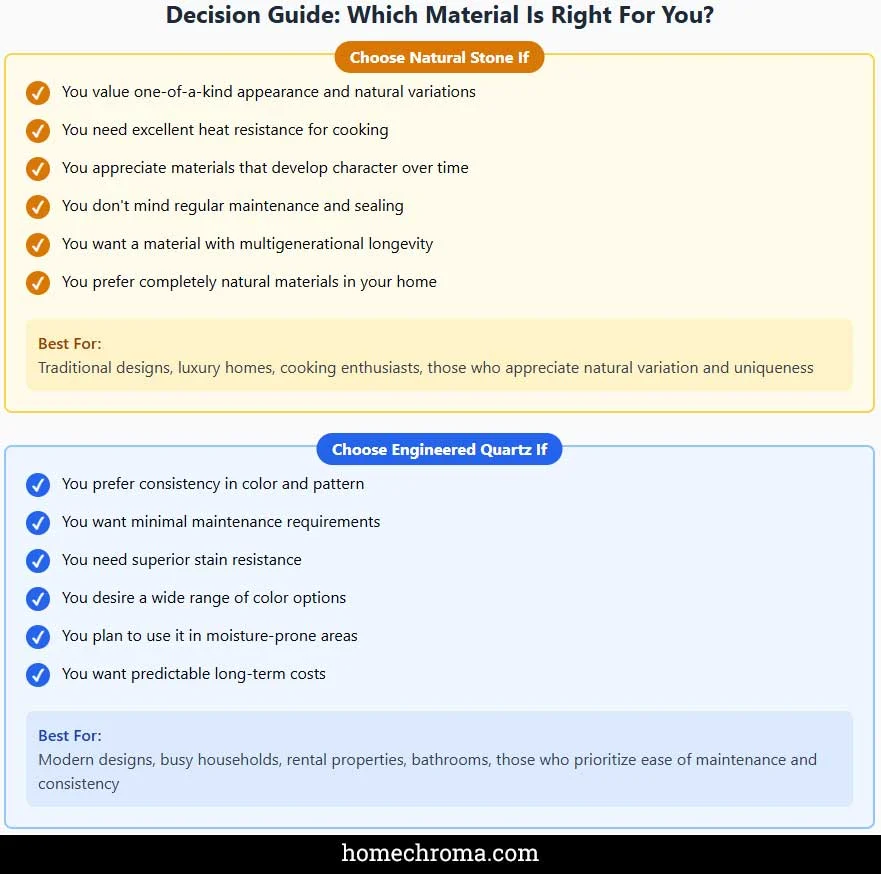

Quick Decision Guide

Final Thoughts

Both natural stone and engineered quartz have earned their popularity for good reason. Natural stone offers unmatched character and uniqueness, while engineered quartz provides consistency and convenience.

Your decision ultimately depends on your priorities: the timeless, unique beauty of natural materials versus the practical, consistent performance of engineered surfaces. Consider your lifestyle, maintenance preferences, and the specific application when making your choice.

Remember that local availability, installation quality, and proper maintenance will significantly impact the performance and longevity of either material.

Dora Decora is a biophilic interior design specialist and passionate blogger. With a deep commitment to integrating nature into living spaces, Dora specializes in creating environments that foster human-nature connections through thoughtful design elements. Her approach emphasizes sustainable materials, natural lighting, and organic patterns that enhance wellbeing and reduce environmental impact.

This post (https://homechroma.com/natural-stone-vs-engineered-quartz-comparison) was originally published by Dora Decora on Home Chroma. As an Amazon Associates partner, we are compensated for all qualifying purchases.